1. INTRODUCTION

The bakery industry’s newest trend is to manufacture fortified cookies or other baked goods made using composite flour [1]. Cookies have several advantages over other ready-to-eat snacks, including a broader consumer base, a longer shelf life due to their low moisture content, higher flexibility, and a healthful dietary experience [2]. Due to their healthy dietary properties, cookies are tempting for protein fortification and other nutritional enhancements. The rising interest in these baked products can be attributed to their nutritional qualities as well as the possibility of employing them in feeding programs and crises [3]. Consumption of whole grains like whole wheat and millet has been recommended as a safe strategy to control weight gain and lower glycemic response, and functionally active food elements such as dietary fibers, antioxidants, probiotics/prebiotics, and polyphenols are beneficial in the prevention of weight problems and other health-related disorders [1,4].

As a consequence of their improved nutritional profile when compared to cereals, pseudo cereals such as buckwheat (Fagopyrum esculentum), quinoa (Chinopodium quinoa), and amaranth (Amaranthus) have acquired global recognition in the nutraceutical industry. Buckwheat (F. esculentum) is a pseudocereal that thrives in low-intensity environments and can provide instant and long-term sustenance to the “Starving World” [5]. Among the several types of buckwheat, sweet buckwheat (F. esculentum Moench) and Tartary buckwheat are the most commonly grown (Fagopyrum tartaricum). It is named in Hindi as “Kuttu,” and it is a Polygonaceae family agricultural plant that has historically been underutilized pseudocereal. Buckwheat grain has a distinctive structure and characteristics compared to wheat grain, including a higher concentration of amino acids (leucine, lysine, histidine, and valine), Vitamin B complex, minerals (magnesium, copper, and iron), catechins, rutin, polyphenols, and other pharmacologic constituents [5]. Consequently, buckwheat offers several health benefits, including strengthening heart health since it is a good source of fiber. Dietary fiber helps to decrease blood cholesterol levels, which lowers the risk of heart disease, diabetes, stroke, and obesity [6]. Buckwheat is also naturally gluten-free; thus, these flours can be consumed by any gluten-intolerant individual (celiac disease) [6,7].

Humans have relied on medicinal plants for food fortification purposes since prehistoric times. The drumstick tree (Moringa oleifera Lam.) is one of the widely utilized plants whose different components (fruit, leaf, and seed) are incorporated into the regular diet for their diverse abilities to treat various health concerns. Increased global interest in employing moringa derivatives as a functional component in nutraceuticals has emerged. Due to appropriate nutritional and bioactive composition, moringa leaves are a potential option for developing nations seeking economical, readily accessible, and high-quality health services in regions where modern medicine is unavailable [8]. Several researches [9-13] have documented the sustainable use of M. oleifera leaf powder (MOLP) in bakery items, including cookies. For instance – [10] replace wheat flour with varying levels of MOLP in the production of cookies. Based on the experimental results, the authors conclude that up to 10% MOLP can be used in the production of cookies that have significant nutritional, textural, and sensory acceptability. Similarly, Tessera et al. [13] reported that the supplementation of MOLP at 5% could improve the bioavailability of Fe, [11] reported that the composite flour cookies together with MOLP could improve the nutritional quality of cookies, Mouminah [14] reported that the increased level of MOLP significantly elevate the nutritional content, but conversely reduce the sensory acceptability, where [12] observed that the consumption of moringa cookies significantly elevate the quality of breastfeeding milk. Based on data from studies that have been documented in the literature, we choose the MOLP in combination with composite flour to enhance the nutritional profile of cookies.

Food fortification promotes economic growth by encouraging the use of commonly accessible sustainable resources, fostering self-sufficiency, and establishing market opportunities for locally produced foods [15]. Furthermore, we hypothesize that buckwheat (F. esculentum) flour and drumstick (M. oleifera Lam.) powder can be incorporated as functional ingredients to improve the overall nutritional quality of cookies. As a result, the present study focused on the production of cookies using buckwheat flour (BWF) and MOLP as a partial replacement for whole wheat flour (WWF). The emphasis study favors high-fiber, low-glycemic cookies. Isomalto-oligosaccharides (IMOs) are used to substitute honey to help diabetics manage blood glucose levels, a growing concern.

2. MATERIALS AND METHODS

2.1. Raw Materials

Raw materials (food grade), namely, peanut butter (Dr Oetkar), baking soda (Weikfield), coconut oil (Organic India), vanilla extract (Urban platter), and honey (Dabur) were procured from the local supermarket of Ambala, Haryana-India. The buckwheat (F. esculentum) and Whole-wheat (Triticum aestivum) flour was procured from the local mill. The MOLP was prepared by following [16]. The VitaFiber IMOs Prebiotic fiber sweetener (IMOs) was purchased from an E-commerce site. The polypropylene (PP) and biaxially oriented polypropylene (BOPP) were bought at a local store in Chandigarh, India, and were used to pack the cookies.

2.2. Chemical Analysis

The proximate analysis of raw material, namely, WWF, BWF cookies (BWFC), MOLP, and prepared cookies were analyzed by the method given by AOAC International [17]; ash content (AOAC, Method no. 923.03). The moisture % (dry basis) was analyzed by following gravimetric method no. 925.10, and the ash content was estimated using an automated muffle furnace (Bionics Scientific, India). The Crude protein and fat content were estimated using Micro-Kjeldahl by following IS: 7219–1973 and IS: 4684–1975, respectively. The total carbohydrate percentage was calculated by the difference method by following [18]. The total polyphenols in prepared cookies were estimated by adopting a colorimetric technique using Folin–Ciocalteu reagent by following the method given by ISO – (ISO 14502–1:2005) [19]. The mineral composition (Ca and Fe) in prepared cookies was estimated using ICP-MS. The NexION 2000 ICP-MS was used for the analysis, and the samples were prepared using a microwave digestion system (PerkinElmer Inc., Connecticut, USA). With the addition of HNO3 and H2O2, 0.25 g of cookie samples was processed in a microwave digester. In addition, the samples were stored in a microwave digester and processed in accordance with the instrument manual. Once digestion was complete, the sample solution was transferred to a volumetric flask, and the volume was determined using ASTM Type-1 water. To make a 1000 ppm stock of standard 0.1, 0.5, 1.0, 5.0, and 10.0 ppm iron and calcium calibration standards.

2.3. Process Standardization

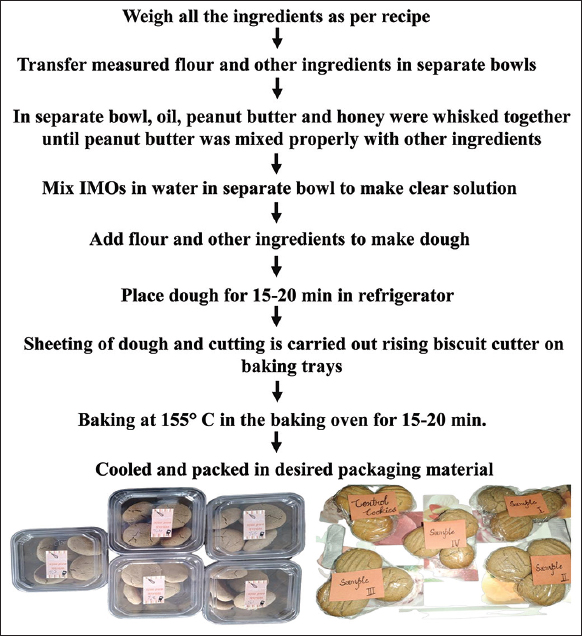

For the preparation of cookies, a standardized method given by [20] was followed with a slight modification in Figure 1. Initially, (n = 4) different WWF and BWF formulations, C1 (80% WWF, 20% WWF), C2 (60% WWF, 40% BWF), C3 (40% WWF, 60% WWF,), and C4 (20% WWF, 80% WWF), were prepared and pre-analyzed for sensory evaluation in comparison with control (100% WWF). Thereafter, (n = 5) cookie formulations were prepared by fortifying MOLP (1%–5%) in 40% WWF, and 20% WWF and again evaluated for sensory acceptability. Based on pre-sensory evaluation (n = 3) formulations BWFC (40% WWF and 60% BWF) and buckwheat and moringa fortified cookies (BWMC) (40% WWF; 60% BWF; and 1% MOLP) were selected for the preparation of final cookies.

| Figure 1: Process standardizes for the preparation of the cookies. [Click here to view] |

2.4. Production of Cookies

Table 1 represents the quantities of ingredients used for the preparation of sensory-acceptable cookies, namely, BWFC with IMOs (BWFC; 40% WWF; and 60% BWF) and buckwheat and MOLP-based cookies with IMOs (BWMC; 40% WWF and 60% BWF together with 2% MOLP) and WWF cookies (WWFC; 100% WWF). To avoid lump formation and consistent mixing of all the components, the flour combination was weighed and sieved, along with the baking powder and baking soda. Other ingredients such as coconut oil, peanut butter, and honey were stirred together in a separate dish until the peanut butter was well combined with the other components. IMOs were mixed with water and added to the flour in the test cookies to replace some of the honey. In the control cookies, no IMOs were added to the flour. The ingredients were mixed to form a dough and the dough was then kneaded until it reached the desired uniformity. The prepared dough was refrigerated for around 15–20 min before sheeting using a wooden rolling pin. The sheet’s thickness was preserved at 2–2.5 mm, and it was hand-cut into round shapes with a cookie cutter and set on a pan. For around 15–20 min, the tray was placed in a preheated OTG oven set to 155°C. The cookies were cooled at room temperature before being wrapped in cling foil and kept at room temperature within the containers for future examination.

Table 1: Formulation of cookies.

| Ingredients | Control cookies | BWFC | BWMC |

|---|---|---|---|

| Whole wheat flour (g) | 100 | 40 | 40 |

| Buckwheat flour (g) | - | 60 | 60 |

| MOLP (g) | - | 2 | 2 |

| Honey (g) | 20 | 10 | 10 |

| Vanilla extract (g) | 3 | 3 | 3 |

| IMOs | - | 25 | 25 |

| Peanut butter (g) | 50 | 50 | 50 |

| Coconut oil (g) | 30 | 30 | 30 |

WWFC: Whole wheat flour cookies, BWFC: Buckwheat flour cookies, BWMC: Buckwheat and moringa-based cookies, MOLP: Moringa oleifera leaf powder, IMOs: Iso-Malto-oligosaccharides.

2.5. Sensory Evaluation

The organoleptic evaluation of prepared cookies was carried out using a 9-point hedonic rating scale, anchored by “like extremely” to “dislike extremely” by following Rangana, [21]. Academic experts in food technology (n = 12; eight men, four women), chefs (n = 2), and semi-trained master’s students (n = 15) who regularly eat cookies and report no history of allergies or intolerance to the listed ingredients serve as the sensory panel (wheat flour, BWF, and MOLP). A training session was placed before the final sensory analysis to explain the purpose of the study as well as the sensory analysis scheme. Each participant then signed a written informed consent form. Following that, a preliminary sensory assessment was carried out on commercial cookies to acquaint the panelists with cookies as well as the sensory evaluation method. Sensory panelists were also advised, not to eat anything pungent or spicy before the test. The cookies, brine solution, and packaged drinking water were supplied separately in the room (natural daylight). To minimize humidification, all cookie samples were labeled and stored in PP and BOPP packaging material. The total mean values received after analyzing the final manufactured cookies were calculated for each sensory parameter, including color, taste, chewiness, texture, aroma, and overall acceptability.

2.6. Shelf-Life Study

The prepared cookies were packed in different packaging materials, that is, BOPP (BOPP – thickness 75 gauges) and PP (PP – thickness 60 gauges) at ambient storage conditions (25 ± 2°C and 65 ± 2% R.H.). The shelf life of cookies was determined over storage duration of 90 days with 30-day intervals. The shelf-life study was based on the sensory evaluation (color, taste, texture, flavor, aroma, and overall acceptability).

2.7. Statistical Analysis

The quantitative estimation of the physicochemical properties of cookies was done in triplicate and is presented in mean ± standard deviation (Mean ± SD). The standard deviation was calculated using Microsoft Excel 2019 (Microsoft Corp., Redmond, WA). The statistical difference was determined using SPSS Statistics for windows, version-16, Chicago Inc. USA, applying analysis of variance at the significance of P ≤ 0.05.

3. RESULTS AND DISCUSSION

3.1. Proximate Composition of Raw Materials

Table 2 represents the average composition; moisture, ash, crude fat, crude protein, fiber, carbohydrate, and energy value of WWF, BWF, and MOLP. Moisture content is an important attribute of bakery products as well as other foodstuffs, and it has been connected as an indication of food shelf-life since higher moisture content encourages microbial growth. The moisture content (%) of WWF was significantly (P ≤ 0.05) higher (12.06%) than MOLP and BWF by the value of 11.20% and 11.60%, respectively. The MOLP had the highest ash content of 2.06%, followed by BWF at 1.65% and WWF at 1.28%. Increased ash content in MOLP is perhaps due to higher quantities of minerals such as calcium, iron, phosphorus, magnesium, and potassium. From the experimental results, it was observed that BWF has the highest concentration of crude fat (3.72 g/100 g) and fiber (8.64 g/100 g), which is significantly (P ≤ 0.05) higher than WWF. This increased concentration of fiber in BWF, followed by MOLP, is possible due to the presence of cellulose and lignin [22], whereas MOLP is rich in dietary soluble fibers, which both help in not only digesting food but also preventing many diseases [23]. MOLP had the highest concentration of crude protein (10.39 g/100 g) and carbohydrates (77.04 g/100 g) among raw materials, due to the presence of amino acids such as arginine, serine, aspartic acid, glutamic acid, threonine, alanine, methionine, lysine, and tryptophan, whereas whole wheat lacks most essential amino acids such as lysine and threonine [1]. The MOLP showed maximum energy values followed by the BWF and WWF with the values of 398.09 Kcal/100 g, 377.03 Kcal/100 g, and 359.05 Kcal/100 g, respectively.

Table 2: Proximate composition of raw materials.

| Parameters | WWF | BWF | MOLP |

|---|---|---|---|

| Moisture (%) | 12.06±0.13a | 11.60±0.11b | 11.20±0.12b |

| Total ash (%) | 1.28±0.02c | 1.65±0.04b | 2.06±0.7a |

| Crude fat (g/100g) | 2.34±0.02c | 3.72±0.06a | 2.89±0.07b |

| Crude protein (g/100g) | 9.73±0.16c | 10.08±0.19b | 10.39±0.14a |

| Total fibre (g/100g) | 5.64±0.25c | 8.64±0.23a | 8.51±0.13a |

| Total carbohydrate (g/100g) | 60.86±1.18c | 75.74±1.32b | 77.04±1.03a |

| Total energy (Kcal/100g) | 359.05±2.18c | 377.03±2.08b | 398.09±2.03a |

The all-replicates values are represented as (Mean±SD) and different superscript along each row denotes significant differences at (P≤0.05). WWF: Whole wheat flour, BWF: Buckwheat flour, MOLP: Moringa oleifera leaf powder.

[24] reported the average composition of MOLP as 7.43% moisture, 50.16% carbohydrates, 22.03% crude fiber, and 20.4% crude protein. The somewhat varied composition of MOLP in comparison to other published research might be attributed to several contributing factors, including variety, growing conditions, geographical regions, processing techniques, and other internal and external variables. For instance, [25] reported that drying temperature has a significant impact on the composition of MOLP, with 10.33% moisture, 2.65% fat, 17.40% fiber, 21.18% protein, and 46.34% carbohydrate when dried at 50°C, and 5.00% moisture, 2.47% fat, 17.61% fiber, 20.75% protein, and 49.08% carbohydrate when dried at 50°C. Furthermore, while the structural and nutritional characteristics of whole wheat and BWF differ, several authors [22,26] revealed that BWF surpassed WWF in terms of protein, minerals, and other phenolic compounds. The aforementioned findings are consistent with those of [22] reported that the average moisture, ash, protein, and carbohydrate content in BWF was 11.60%, 1.42%, 8.73%, and 75.74%, respectively.

3.2. Proximate Analysis of Cookies

The nutritional composition of cookies; WWFC; buckwheat and WWFC (BWFC); and BWMC is tabulated in Table 3. The moisture content in prepared cookies varied from 4.21 to 4.86%, with a modest variation in moisture content decrease, this may be due to the incorporation of MOLP. BWMC had low moisture content, that is, 4.21%; these cookies will have a longer shelf life than the other two samples.

Table 3: Nutritional evaluation of cookies.

| Samples | Control | BWFC | BWMC |

|---|---|---|---|

| Moisture (%) | 4.86±0.13a | 4.65±0.10a | 4.21±0.08b |

| Total ash (%) | 1.64±0.07b | 1.75±0.04ab | 2.56±0.03a |

| Fat (g/100 g) | 12.95±0.12a | 12.98±0.11a | 12.38±0.06b |

| Protein (g/100g) | 12.66±0.05b | 12.61±0.06b | 13.79±0.07a |

| Fibre (g/100g) | 1.84±0.06b | 2.62±0.09ab | 6.74±0.09a |

| Carbohydrate (g/100g) | 61.89±1.05b | 62.56±0.55b | 69.74±1.02a |

| TPC (mg GAE/g) | 7.67±0.23b | 9.75±0.17a | 10.99±0.19a |

| Fe (mg/100g) | 4.76±0.14c | 15.51±0.11b | 20.35±0.64a |

| Ca (mg/100g) | 21.25±0.53c | 45.27±0.82b | 50.89±0.91a |

| Energy Kcal/100g) | 414.50±1.23b | 414.75±2.04a | 414.54±2.12b |

The all-replicates values are represented as (Mean±SD) and different superscript along each row denotes significant differences at (P≤0.05). Control: Whole wheat flour cookies, BWFC: Buckwheat flour cookies, BWMC: Buckwheat moringa-based cookies, TPC: Total phenolic contents.

After baking, the moisture level of cookies should be <5%, resulting in a crisp texture and high storage stability [27]. The fat content of prepared cookies ranged from 12.38% to 12.95%. Cookies supplemented with BWFC retained the highest fat % by a value of 12.98%, while MOLP was found to have the lowest fat %, which is likely due to the oil retention ability of BWF during the baking process [22]. Furthermore, increased oil retention enhances the mouth feel, preserves the flavor of baked items, and reduces the risk of rancidity [7]. The maximum ash content, that is, 2.56% was found in BWMC, followed by BWFC and WWFC at 1.75% and 1.64%, respectively. This rise in ash level in BWMC and BWFC is most likely due to the high mineral content (Fe, Cu, Mg, Ca, and Zn) in both MOLP and BBF [25].

While estimating the protein, fiber, and carbohydrates content in prepared cookies a significant difference (P ≤ 0.05) among all the treatments, where the maximum protein (13.79%), fiber (6.74%), and carbohydrates (69.74%) were found in BWMC, followed by BWFC and WWFC. The carbohydrate content in prepared cookies ranged from 61.89% to 69.74%, with BWMC scoring the maximum and control cookies scoring the lowest, and BWFC scoring in between the two samples, because BWMC and BWFC contain IMOs, a complex form of carbohydrate is always a better option for diabetic patients. The maximum fiber content (3.51%) was observed in BWMC, which is significantly higher (P ≤ 0.05) among the treatments, this increase in fiber content in BWMC is due to the natural occurrence of elevated levels of dietary fiber in both BWF and MOLP [28]. The incorporation of BWF together with WWF in the preparation of cookies significantly elevates the level of crude fiber as well as other nutritional parameters [7]. According to the food and drug administration, the recommended total dietary fiber intakes are about 25 g daily, of which about 25% (about 6 g) should be soluble fiber. We obtained the fiber content of 6.74%, which is lower than the maximum consumption limit [29]. According to [30], a food is only considered to be a “source of fiber” if it contains at least 3 g/100 g fiber, or at least 1.5 g/100 kcal fiber. On the other hand, food is only considered to be “high in fiber” if it contains at least 6 g/100 g fiber, or at least 3 g/100 kcal fiber.

The calorific value of the BWFC sample was calculated maximum had value, which was likely due to the high-fat content. [31] reported that reduced fat content leads to lower energy values, whereas greater fat contributes to higher energy values and enhances lipid oxidation. In accordance with present study, [32] reported, that the physicochemical parameters, namely, moisture %, protein %, fiber %, fat %, and carbohydrates % in cookies prepared with wheat flour and cookies prepared with wheat flour (97.5%) together with M. olrifera powder (2.5%) were 7.75%, 10.56%, 2.50%, 14.21, and 61.86% and 7.29%, 12.20%, 2.42%, 14.92%, and 59.27%, respectively.

The total phenolic contents (TPC) in prepared cookies ranged from 7.67 to 10.99 mg GAE/g. Furthermore, the TPC was noted as maximum (10.99 mg GAE/g) in BWMC, and this elevated level of TPC is likely to the incorporation of MOLP. The TPC in whole flour and moringa powder supplement (2.5%) based cookies was reported as 19.39 and 30.17 mg GAE/100 g [32]. Fapetu et al. [32] observed that gradually increasing the amount of MOLP in their cookies increased the phenolic content because this flour is high in antioxidants such as quercetin and chlorogenic acid. There is a strong correlation between phenolic content and antioxidant activity, which boosts immunity and combats chronic diseases [33]. In contrast to WWF, the phenolic content of the comparable blends reduced dramatically as the amount of BWF in the blend decreased [7]. While estimating the minerals content (Ca and Fe) in prepared cookies, it was observed that the BWMC exhibits maximum concentration, that is, 20.35 and 50.89 mg/100 g which is significantly (P ≤ 0.05) higher than WWFC and BWFC. Rajput et al. [24] reported that the concentration of Ca and Fe in WWF biscuits fortified with MOLP at different levels, that is, 2% (40.19 and 1.62 mg/100 g), 4% (55.06 and 1.94 mg/100 g), and 6% (68.26 and 2.22 mg/100 g), respectively. The increase of Ca while fortifying the MOLP in cookies was also observed [25]. As a result, incorporating MOLP into baked products significantly increases mineral content, and this fortification can be employed at an industrial scale to address malnutrition and micronutrient deficiencies.

3.3. Sensory Evaluation

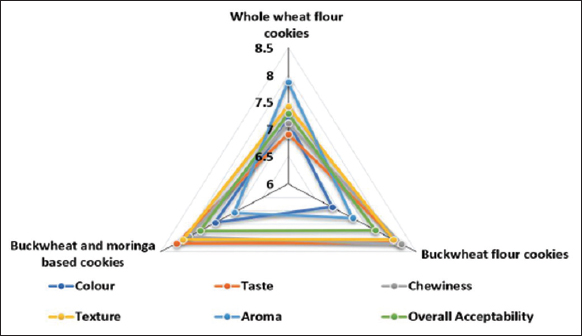

Figure 2 depicts the sensory ratings of cookies. In terms of color, the BWFC cookies scored the highest, followed by the control and BWF, which is consistent with [7] because wheat flour does not affect the color of the cookies, whereas BWF adds a darker color to the cookies and MOLP up to 3% has no effect on the color quality of cookies. Sensory score findings indicate that the taste of cookies improved with the incorporation of both buckwheat and MOLP. This is because both of the flours have a typical flavor that samples mixed with these flours. [34] also observed that BWF up to 70% and MOLP up to 3% resulted in good sensory acceptability. The addition of BWF increases chewiness; this finding was consistent with [35], which found that incorporating increased chewiness because BWF is non-glutenous and has a high moisture content, which contributes to the chewiness of cookies. Sensory panelists scored a maximum for both BWF and BWM cookies, and the samples with the addition of BWF and MOLP improved the texture of the cookies. Similar findings were observed by [34], who found that the addition of BWF up to 70% and MOLP up to 3% improved the texture of cookies. In terms of aroma, the BWM followed by BWF got a minimum score by sensory panelists, this low score may be due to the earthy and grassy smell of BWF and M. oleifera, respectively, similar observations were also observed by [36]. Moreover, the BWM followed by BWFC scored the highest overall acceptance score from panelists; hence, we recommend that this formulation be used by the bakery-related industry to offer unique value-added cookies that will be enjoyed by diverse age groups.

| Figure 2: Sensory evaluation of cookies. [Click here to view] |

3.4. Storage Study

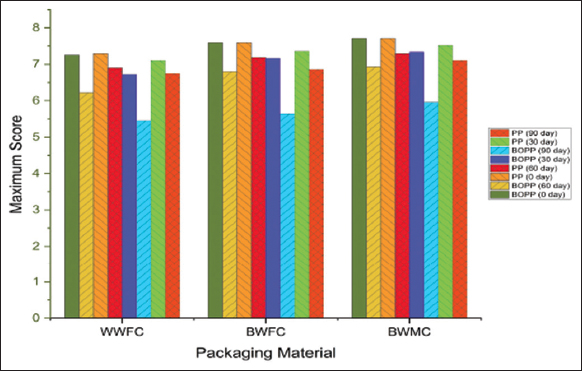

Table 4 shows the shelf-life assessment of cookies packed in different packaging materials. The packaging material PP exhibited a non-significant change in BWMC (7.71–7.10) from 0 to 90 days. Concerning another sample BWFC, the PP packaging began to exhibit a somewhat significant alteration after 60 days, but the cookies remained edible as they scored 6.86 on the hedonic scale, which suggests modestly liked; hence, the overall score stayed from 7.60 to 6.86 from 0 to 90 days. Further, the WWFC sample packed in PP exhibited a considerable shift even before BWFC after 30 days as it scored 6.90, even though they were still in a pleasant position; hence, the WWFC scores from 0 to 90 days remained from 7.29 to 6.74. However, a significant difference (P ≤ 0.05) in sensory characteristics was identified between WWFC and BWFC after storage under different packing materials, which might be attributable to moisture gain as WWF and BWF contains more moisture than MOLP. Likewise, the scores for samples packed in BOPP varied considerably. For sample BWMC, the scores from 0 to 90 days remained between 7.71 and 5.96. After 30 days, the sample scores started going down gradually, and by the 90th day, it was on a scale of 5, implying cookies did not remain in likeable status by the panel lists. The scores for BWFC storage under BOPP remained between 7.60 and 5.64 even after 90 days. The sample also changed significantly after 30 days, but the scores for WWFC changed significantly on the 30th day itself, going from 7.25 to 5.45 from 0 to 90 days. In conclusion, samples packed in BOPP for up to 90 days at room temperature gain more moisture than samples packed in PP, so the organoleptic quality of cookies packed in BOPP was less good than cookies packed in PP.

Table 4: Shelf-life study of cookies packed in different packaging materials.

| Packaging material | Storage period (days) | WWFC (control) | BWFC | BWMC |

|---|---|---|---|---|

| BOPP | 0 | 7.25a | 7.60a | 7.71a |

| 30 | 6.72b | 7.17a | 7.34a | |

| 60 | 6.22b | 6.80b | 6.93b | |

| 90 | 5.45c | 5.64c | 5.96c | |

| PP | 0 | 7.29a | 7.60a | 7.71a |

| 30 | 7.10a | 7.36a | 7.52a | |

| 60 | 6.90b | 7.19a | 7.29a | |

| 90 | 6.74b | 6.86b | 7.10a |

The all-replicates values are represented as (Mean±SD) and different superscript along each row denotes significant differences at (P≤0.05). PP: Polypropylene, BOPP: Biaxially oriented polypropylene, WWFC: Whole wheat flour cookies, BWFC: Buckwheat flour cookies, BWMC: Buckwheat moringa cookies.

Taking that into consideration, sample BWMC still surpassed the other two samples significantly with the addition of MOLP, which has lower moisture content than BWF and WWF alone. As a result, both PP had the highest sensory scores for overall acceptability over 90 days, which were much higher than BOPP, as shown in Figure 3. Consequently, we conclude that PP is a suitable material for preserving cookies.

| Figure 3: Storage stability of cookies under different packaging material. [Click here to view] |

3.5. Limitation of the Study

Concerning the study’s limitations, the developed cookies need to have their anti-oxidant potential tested using methods such as DPPH, ABTS, and FRAP. In addition, the developed product has to have its bioavailability and bioaccessibility tested using a placebo, and clinical studies are required. The sorption isotherm might be used as storage study validation under various circumstances and packing materials.

4. CONCLUSION

The present study’s findings data suggest that incorporating MOLP (2%) with BWF (60%) into cookies had a substantial effect on the cookie’s chemical, sensory, and shelf-life characteristics as well as on individual health. The improved TPC, fiber, carbohydrate, protein, and minerals (Ca, Fe) of the BWFC and BWMC above WWFC are a probable indication that the incorporation of BWF and MOLP together yields cookies with improved nutritional and bioactive features. Furthermore, the cookies may be especially helpful for diabetes patients due to their decreased glycemic index and improved glucose homeostasis. Buckwheat does contain gluten, though, so it could potentially be advantageous for those who have celiac disease. In addition, PP can effectively use as a packaging material for cookies with extended shelf-life. The intended MOLP and buckwheat-based cookie recipe may represent an innovative formulation that calls for additional research into its whole composition and alterations connected to storage over time under various storage materials. Several clinical investigations are also required to confirm its efficacy and safety for intake. In brief, despite the limitations indicated above, our analysis encourages further exploration of alternative flours and ingredients to fully understand its nutritional and therapeutic features. In addition to PP and BOPP, innovative packaging materials that are environmentally beneficial may be tailored to increase the shelf-life of cookies

5. AUTHORS’ CONTRIBUTIONS

All authors made substantial contributions to conception and design, acquisition of data, or analysis and interpretation of data; took part in drafting the article or revising it critically for important intellectual content; agreed to submit to the current journal; gave final approval of the version to be published; and agreed to be accountable for all aspects of the work. All the authors are eligible to be an author as per the International Committee of Medical Journal Editors (ICMJE) requirements/guidelines.

6. FUNDING

There is no funding to this report.

7. CONFLICTS OF INTEREST

The authors report no financial or any other conflicts of interest in this work.

8. ETHICAL APPROVALS

This study does not involve experiments on animals or human subjects.

9. DATA AVAILABILITY

All data generated and analyzed are included within this research article.

10. PUBLISHER’S NOTE

This journal remains neutral with regard to jurisdictional claims in published institutional affiliation.

REFERENCES

1. Siddiqui SA, Mahmud MM, Abdi G, Wanich U, Farooqi MQ, Settapramote N, et al. New alternatives from sustainable sources to wheat in bakery foods:Science, technology, and challenges. J Food Biochem 2022;46:e14185. [CrossRef]

2. Chavan RS, Sandeep K, Basu S, Bhatt S. Biscuits, cookies, and crackers:Chemistry and manufacture. In:Encyclopedia of Food and Health. Amsterdam:Elsevier;2016. 437-44. [CrossRef]

3. Aljobair MO. Physicochemical, nutritional, and sensory quality and storage stability of cookies:Effect of clove powder. Int J Food Prop 2022;25:1009-20. [CrossRef]

4. Ali AM, Shaban HH. Cookies processing from composite flours of cereals with high nutritional value. Curr Sci Int 2022;11:140-53.

5. Krishnaswamy GG, Parameshwari S. A concise review on buckwheat materials based ready to serve and ready to eat food products. Mater Today Proc 2022;66:783-8. [CrossRef]

6. Nakamura K, Naramoto K, Koyama M. Blood-pressure-lowering effect of fermented buckwheat sprouts in spontaneously hypertensive rats. J Funct Foods 2013;5:406-15. [CrossRef]

7. Jan U, Gani A, Ahmad M, Shah U, Baba WN, Masoodi FA, et al. Characterization of cookies made from wheat flour blended with buckwheat flour and effect on antioxidant properties. J Food Sci Technol 2015;52:6334-44. [CrossRef]

8. Xiao X, Wang J, Meng C, Liang W, Wang T, Zhou B, et al. Moringa oleifera lam and its therapeutic effects in immune disorders. Front Pharmacol 2020;17:566783. [CrossRef]

9. Agrahar-Murugkar D, Dwivedi S, Dixit-Bajpai P, Kumar M. Effect of natural fortification with calcium and protein rich ingredients on texture, nutritional quality and sensory acceptance of cookies. Nutr Food Sci 2018;48:807-18. [CrossRef]

10. Dachana KB, Rajiv J, Indrani D, Prakash J. Effect of dried moringa (Moringa oleifera lam) leaves on rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. J Food Qual 2010;33:660-77. [CrossRef]

11. Igbabul B, Ogunrinde MD, Amove J. Proximate, micronutrient composition, physical and sensory properties of cookies produced from wheat, sweet detar and moringa leaf flour blends. Curr Res Nutr Food Sci J 2018;6:690-9. [CrossRef]

12. Sumarni, Puspasari I, Mallongi A, Yane E, Sekarani A. Effect of Moringa oleifera cookies to improve quality of breastmilk. Enferm Clín 2020;30:99-103. [CrossRef]

13. Tessera GM, Haile A, Kinfe E. Bioavailability of minerals in cookies developed from blend of Moringa leaf powder and wheat flour for iron deficient lactating mothers. Int J Food Sci Nutr Eng 2015;5:226-32.

14. Mouminah HH. Effect of dried Moringa oleifera leaves on the nutritional and organoleptic characteristics of cookies. Alex Sci Exch J 2015;36:297-302. [CrossRef]

15. Chadare FJ, Idohou R, Nago E, Affonfere M, Agossadou J, Fassinou TK, et al. Conventional and food-to-food fortification:An appraisal of past practices and lessons learned. Food Sci Nutr 2019;7:2781-95. [CrossRef]

16. Reddy BH, Pradeep P, Padmavathi TV. Development and evaluation of value-added products from moringa leaves. J Pharmacogn Phytochem 2020;9:660-3. [CrossRef]

17. AOAC International. “Association of Official Analytical Chemists.“(2005).

18. Jain A, Mehra R, Garhwal R, Rafiq S, Sharma S, Singh B, et al. Manufacturing and characterization of whey and stevia-based popsicles enriched with concentrated beetroot juice. J Food Sci Technol 2022;59:3591-9. [CrossRef]

19. International Organization for Standardization. ISO 14502-1:2005-Determination of Substances Characteristic of Green and Black Tea-part 1:Content of Total Polyphenols in Tea-colorimetric Method Using Folin-Ciocalteu Reagent. Switzerland:International Organization for Standardization;2005.

20. Martinez-Saez N, Hochkogler CM, Somoza V, Del Castillo MD. Biscuits with no added sugar containing stevia, coffee fibre and fructooligosaccharides modifies a-glucosidase activity and the release of GLP-1 from HuTu-80 cells and serotonin from Caco-2 cells after in vitro digestion. Nutrients 2017;9:694. [CrossRef]

21. Rangana S. Manual of Analysis of Fruit and Vegetable Products. New York:Tata McGraw-Hill;1979.

22. Baljeet SY, Ritika BY, Roshan LY. Studies on functional properties and incorporation of buckwheat flour for biscuit making. Int Food Res J 2010;17:1067-76.

23. Ogunsina BS, Radha C, Indrani D. Quality characteristics of bread and cookies enriched with debittered Moringa oleifera seed flour. Int J Food Sci Nutr 2011;62:185-94. [CrossRef]

24. Rajput H, Prasad SG, Srivastav P. Nutritional quality analysis of dry moringa powder varity-PKM-1. Pharm Innov 2019;8:95-8.

25. Alakali JS, Kucha CT, Rabiu IA. Effect of drying temperature on the nutritional quality of Moringa oleifera leaves. Afr J Food Sci 2015;9:395-9. [CrossRef]

26. Inglett GE, Chen D, Berhow MA, Lee S. Antioxidant activity of commercial buckwheat flours and their free and bound phenolic compositions. Food Chem 2011;125:923-9. [CrossRef]

27. Hui YH, Corke H, De Leyn I, Nip WK, Cross NA. Bakery Products:Science and Technology. United States:John Wiley and Sons;2008.

28. González-Burgos E, Ureña-Vacas I, Sánchez M, Gómez-Serranillos MP. Nutritional value of Moringa oleifera lam. leaf powder extracts and their neuroprotective effects via antioxidative and mitochondrial regulation. Nutrients 2021;13:2203. [CrossRef]

29. CFR-Code of Federal Regulations Title 21. Available from:https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=101.77

30. Pasqualone A, Laddomada B, Boukid F, De Angelis D, Summo C. Use of almond skins to improve nutritional and functional properties of biscuits:An example of upcycling. Foods 2020;9:1705. [CrossRef]

31. Anwar F, Latif S, Ashraf M, Gilani AH. Moringa oleifera:A food plant with multiple medicinal uses. Phytother Res 2007;21:17-25. [CrossRef]

32. Fapetu AP, Karigidi KO, Akintimehin ES, Olawuwo T, Adetuyi FO. Effect of partial substitution of wheat flour with Moringa oleifera leaf powder on physical, nutritional, antioxidant and antidiabetic properties of cookies. Bull Natl Res Cent 2022;46:53. [CrossRef]

33. Giuberti G, Bresciani A, Cervini M, Frustace A, Marti A. Moringa oleifera L. leaf powder as ingredient in gluten-free biscuits:Nutritional and physicochemical characteristics. Eur Food Res Technol 2021;247:687-94. [CrossRef]

34. Dhillon B, Wiesenborn D, Sidhu H, Wolf-Hall C. Improved microbial quality of buckwheat using antimicrobial solutions in a fluidized bed. J Food Sci 2012;77:E98-103. [CrossRef]

35. Filip?ev B, Šimurina O, Saka?M, Sedej I, Jovanov P, Pestori?M, et al. Feasibility of use of buckwheat flour as an ingredient in ginger nut biscuit formulation. Food Chem 2011;125:164-70. [CrossRef]

36. Ajibola C, Oyerinde V, Adeniyan O. Physicochemical and antioxidant properties of whole-wheat biscuits incorporated with Moringa oleifera leaves and cocoa powder. J Sci Res Rep 2015;7:195-206. [CrossRef]